Rubber Material Testing and Fatigue Life Assessment

Technology Partner

We provide end-to-end testing and simulation solutions for rubber and elastomer components, combining laboratory characterization with advanced fatigue life prediction tools. Our services help manufacturers, designers, and R&D teams improve material performance, durability, and safety while reducing development time and cost.

Rubber & Elastomer CAE Services: Fatigue, Durability, and Performance Analysis

Rubber and elastomer components are widely used in automotive, aerospace, industrial machinery, and consumer products due to their flexibility, damping characteristics, and resilience. Accurate prediction of their behavior under complex loading and environmental conditions is essential for durability, reliability, and product optimization. Our CAE services provide comprehensive solutions spanning material characterization, modeling, and lifecycle simulation.

1. Material Characterization & Constitutive Modeling

-

Non-linear material modeling of elastomers and rubbers under static and dynamic loads.

-

Hyperelastic material models: Neo-Hookean, Mooney-Rivlin, Ogden, Arruda-Boyce.

-

Viscoelastic modeling for time-dependent response prediction.

-

Temperature-dependent and rate-dependent material behavior modeling.

-

Material property extraction from laboratory tests: tensile, compression, shear, cyclic fatigue, and creep tests.

-

Integration of experimental data into predictive CAE models.

2. Finite Element Modeling (FEM) of Rubber Components

-

High-fidelity 3D and 2D finite element modeling of rubber and elastomer parts.

-

Contact modeling with metal, plastic, and composite interfaces.

-

Large deformation analysis and non-linear kinematics.

-

Multi-physics simulations (thermal, structural, vibration) for real-world operating conditions.

3. Fatigue Analysis of Rubber Components

-

Predicting fatigue life under multiaxial, variable amplitude, and complex cyclic loading.

-

Simulation of crack initiation and propagation using advanced fatigue solvers.

-

Application of stress-life (S-N) and strain-life (ε-N) approaches.

-

Integration of endurance limits and mean stress effects.

-

Fatigue assessment under combined mechanical, thermal, and environmental loads.

4. Durability & Lifecycle Prediction

-

Lifetime prediction under dynamic loading conditions.

-

Modeling of aging, environmental degradation, and chemical exposure effects.

-

Viscoelastic and hyperelastic response prediction over extended cycles.

-

Cumulative damage modeling for safety-critical applications.

-

Optimization of component geometry and material for extended durability.

5. Failure & Fracture Analysis

-

Identification of critical stress and strain regions.

-

Simulation of tear, wear, and fracture behavior.

-

Use of virtual crack closure technique (VCCT) and cohesive zone modeling (CZM) for crack growth simulation.

-

Analysis of sealing performance, compression set, and hysteresis energy loss.

-

Prediction of failure under extreme temperature, load, or frequency conditions.

6. Optimization & Design Support

-

Design modifications to improve fatigue life and durability.

-

Topology and shape optimization for weight reduction while maintaining performance.

-

Sensitivity studies to assess the effect of material, geometry, and load variations.

-

Virtual prototyping to reduce physical testing cycles.

-

Cost-efficient design recommendations without compromising reliability.

7. Advanced Simulation Techniques

-

Multi-scale modeling to capture microstructure effects on fatigue and durability.

-

Integration of AI/ML-based predictive models for accelerated life estimation.

-

Coupled thermo-mechanical simulations for real-world operating conditions.

-

Parametric studies for product optimization.

8. Applications

-

Automotive: engine mounts, bushings, seals, tires, vibration isolators.

-

Aerospace: vibration damping components, seals, and gaskets.

-

Industrial machinery: flexible joints, couplings, dampers.

-

Consumer products: wearable devices, footwear, flexible electronics.

ENDURICA Elastomer Characterization Services

Endurica’s characterization services provide precise, physics-informed insights into the fatigue performance of elastomers. Our suite of tests equips you with the critical material parameters needed for accurate simulations and product design optimization. Endurica’s Fatigue Property Mapping service provides all the input you need for your product simulations, helping you understand and predict material behavior under real-world conditions.

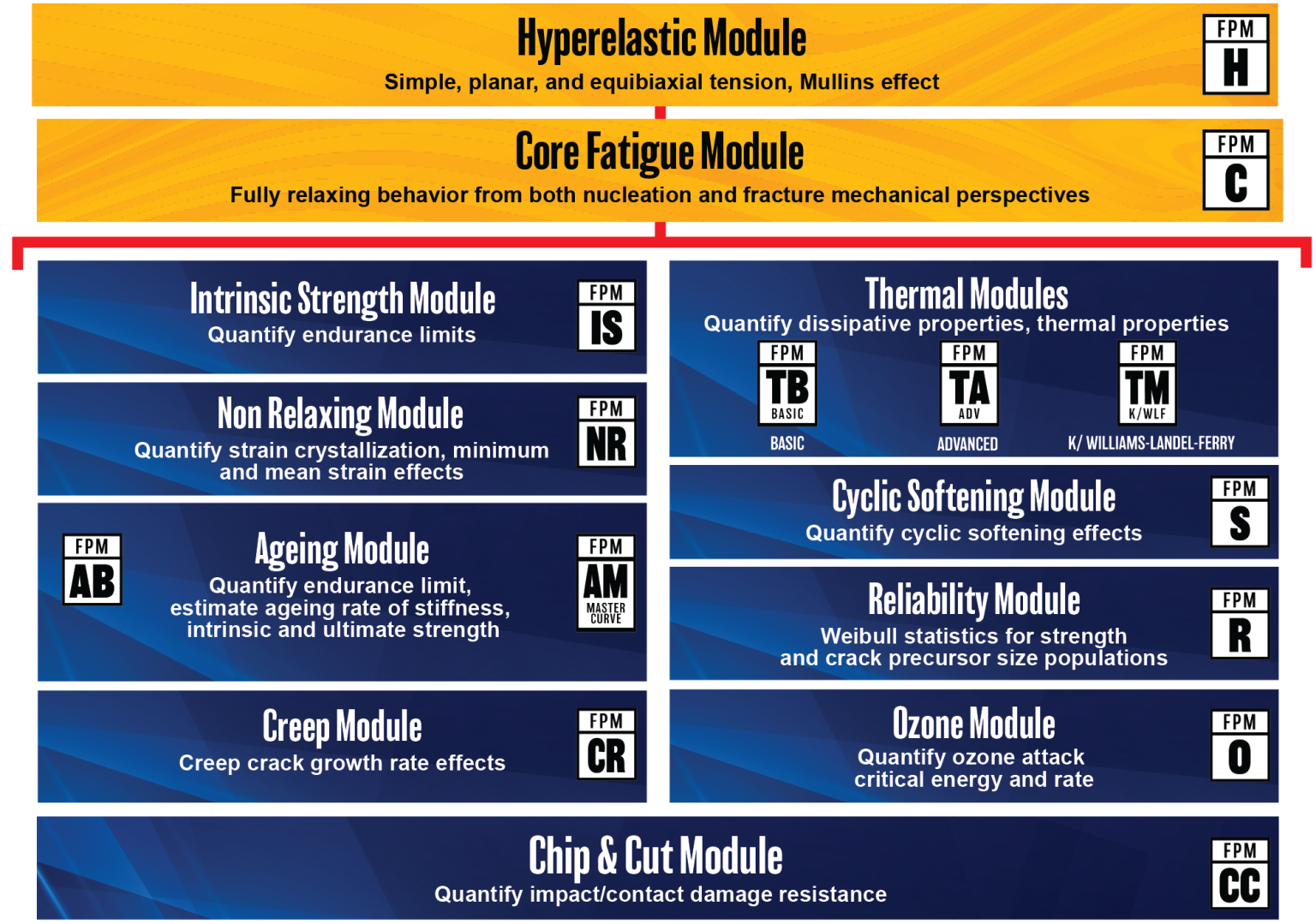

Fatigue Property MappingTM characterization protocols systematically measure the factors that govern durability. The resulting engineering parameters are ready to use with durability simulation codes including Endurica CLTM, Endurica DTTM, Endurica EIETM, and Endurica MPTM. These powerful and efficient tests show how your rubber part endures under realistic operating conditions. Begin with the Core Fatigue and Hyperelastic modules, then add on the items you need to get the physics just right in your analysis.

Why engineers choose Endurica characterization services

- Material parameters ready to use with simulation software: Abaqus, ANSYS, Marc, fe-safe/Rubber™ and Endurica CL™

- Full support for both nucleation (ε-N) or (σ-N) and crack propagation (da/dN) analysis methods

- Accurate and timely results via uniquely reliable and productive test strategies

- Reduced risk and cost of development iterations when you take your material’s fatigue capabilities into account

How our characterization modules work together

While the Hyperelastic Module and the Core Fatigue Module are mandatory for any test, you can build a testing regimen that’s specific to your material to get the physics right.